REGULATEURS EUROPA monitoring and surveillance systems can be as simple or complex as the application demands. From simple LED and LCD displays to comprehensive touch screen-based systems and ship wide monitoring. It is normal RE practice to keep monitoring and safety as separate functions to avoid common mode failures that could endanger the machinery. Whilst most applications require digital and/or screen-based monitoring displays REGULATEURS EUROPA can offer a range of solutions including direct reading local engine panels.

Marine Monitoring Systems

Engine Monitoring

Engine Parameters

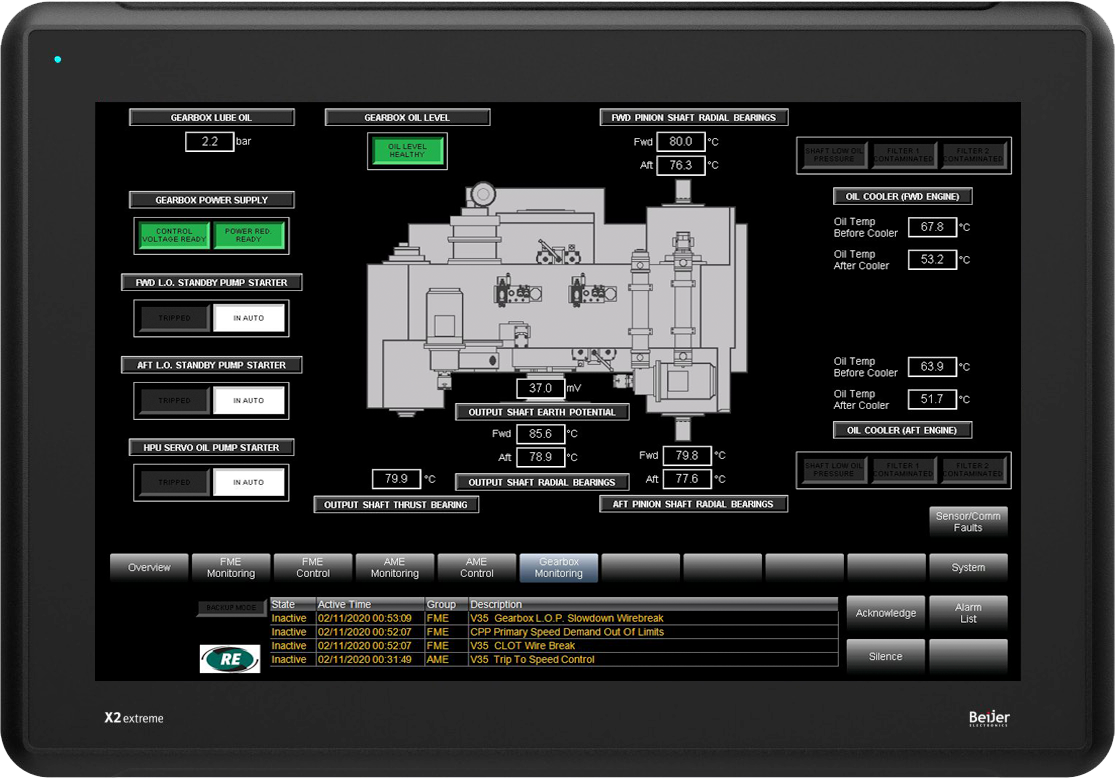

Gearbox Monitoring

Oil Splash

Marine Monitoring Systems

It is normal REGULATEURS EUROPA practice to keep monitoring and safety as separate functions to avoid common mode failures that could endanger the machinery.

SeaMACS Integrated Automation System

FuelMACS Fuel Performance System

SeaMACS Integrated Automation System

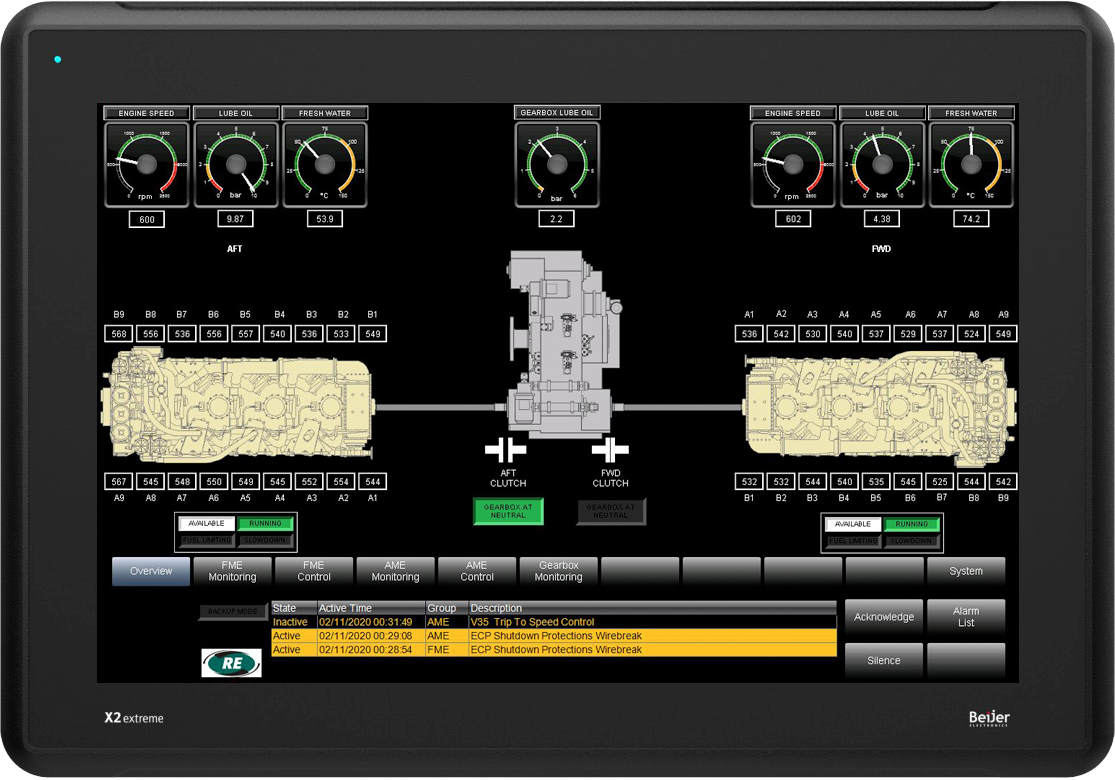

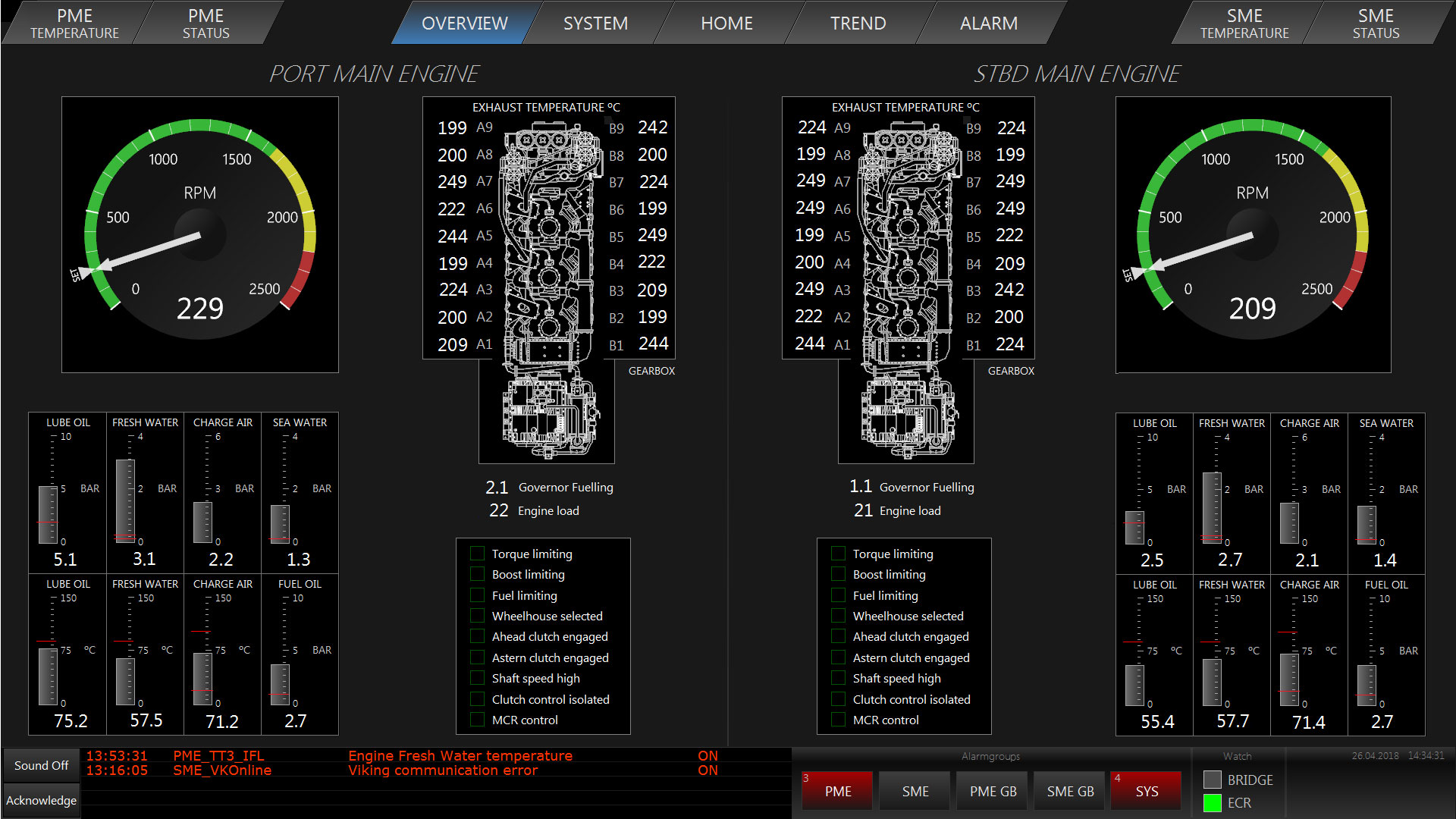

Screen based monitoring systems are popular in many marine applications. RE can custom design screens and/or integrate SeaMACS monitoring displays from their sister company HEINZMANN Automation.

Screen based monitoring systems are popular in many marine applications. RE can custom design screens and/or integrate SeaMACS monitoring displays from their sister company HEINZMANN Automation.

- Scalable system for monitoring of vessel machinery and associated equipment.

- Interfaces for trends, reports, alarms and processes, optionally extendable by video surveillance and more.

- Customizable, flexible architecture for scalability and redundant system for outmost reliability.

Visit HEINZMANN Automation website for detailed system description

FuelMACS Fuel Performance System

- Designed as an onboard tool to save fuel and also as a management tool

- Several ships can be monitored and compared at the same time from a management office on shore

- Data can be collected live or at regular intervals depending on customer requirement

- Existing hardware can be used in order to keep implementation costs down

- The system can also be set up with a service link to our service department