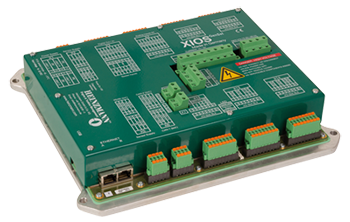

The basic version of XIOS UC consists of the Main board (MC), extendable by up to 5 extension modules (MA) and an Expander Board MD1 or MD2.

I/O capacity of the Main Board:

| Analogue/digital input | Digital output | Hall pick-up | Sensor supply |

| 11x | 2x, max. 4A | 2x | 2x (5 or 12 VDC configurable) |

The XIOS Expander boards MD1 or MD2 offer options for connecting further Extension Boards (MA).

I/O capacity of the Expander Board MD1:

| Analogue/digital input | Digital input | Digital output | Inductive pick-up | Sensor supply | Additional slots |

| 8x | 2x | 2x, max. 4A | 2x | 1x (5 or 12 VDC configurable) | 6x board MA |

Board MD2 is required for the XIOSGenSet and XIOSCHP applications.

I/O capacity of the Expander Board MD2: all possibilities of MD1 and in addition

| Digital Input | Analogue input | AVR output | Relay output | Addtional slots |

| 4x, isolated | 6x AC voltage (3x bus und 3x generator) 4x AC phase current, max. 5 A |

1x | 1x | 3x board MA |

Each of the Extension Modules provides 2 (if isolated), 4 or 8 (if input-only) I/O channels, resulting in a great variety of

configuration options:

| Module type | Function |

| A2 | 4x analogue or digital output, monitored, 0...5 VDC (11 mA), 0...24 mA digital output, max. 1 A PWM controlled (0...100 %) |

| A3 | 4x analogue or digital input, 0...5/10/36 VDC, 0...24 mA temperature input Pt 1000, Pt 200, Pt 100, Ni 1000, NTC 2x sensor supply (5/12 VDC configurable, 50 mA or VBAT) |

| A4 | 2x analogue or digital input, electrically isolated, 0...5/10/36 VDC, 0...24 mA temperature input Pt 1000, Pt 200, Pt 100, Ni 1000, NTC 2x sensor supply (5 VDC, 50 mA) |

| A5 | 2x analogue or digital output, electrically isolated, 0...5 VDC (2.5 mA), 0...24 mA digital output: 60 VDC/40 VAC, 400 mA static, optional: 400 VDC/280 VAC, 100 mA |

| A6 | 2x analogue or digital output, electrically isolated, monitored, 0...5 VDC (10 mA), 0...24 mA |

| A7 | 6x digital input, 9...36 VDC |

| A8 | up to 4x digital output, high or low-side, current read back for control-loop applications, thermal shutdown |

| A1 | 2x thermocouple amplifier, electrically isolated, (J/K/E/R/S/B/N), configurable gain and offset |

| A9 | 1x H bridge output, up to 8 A static current, current read back for control-loop applications |